Production of lithium batteries in Europe

Lithium, with its high energy density, is a critical raw material for battery production. Due to the electrification of transportation and the growing need to store renewable energy, the demand for lithium batteries in Europe is growing rapidly. To meet the growing demand, it is important to scale-up the production of lithium-based batteries in Europe. Currently, Europe still faces a shortage of accessible and affordable lithium, as well as the necessary production capacity to convert the lithium for use in batteries.

Developing European value chains for sustainable battery production

The development of Nobian's innovative lithium chloride conversion process aims to support Europe’s lithium supply and production capacity. By utilizing Nobian's existing chlor-alkali infrastructure and capabilities in the Netherlands and Germany, lithium-bearing brine can be converted into lithium hydroxide monohydrate (LHM) using an innovative production method. Lithium chloride brine (a highly concentrated solution of salt in water), is converted into lithium hydroxide through controlled crystallization and electrolysis. This method is more efficient and sustainable than existing production methods, leading to lower investment needs and lower operating costs.

Battery chemicals

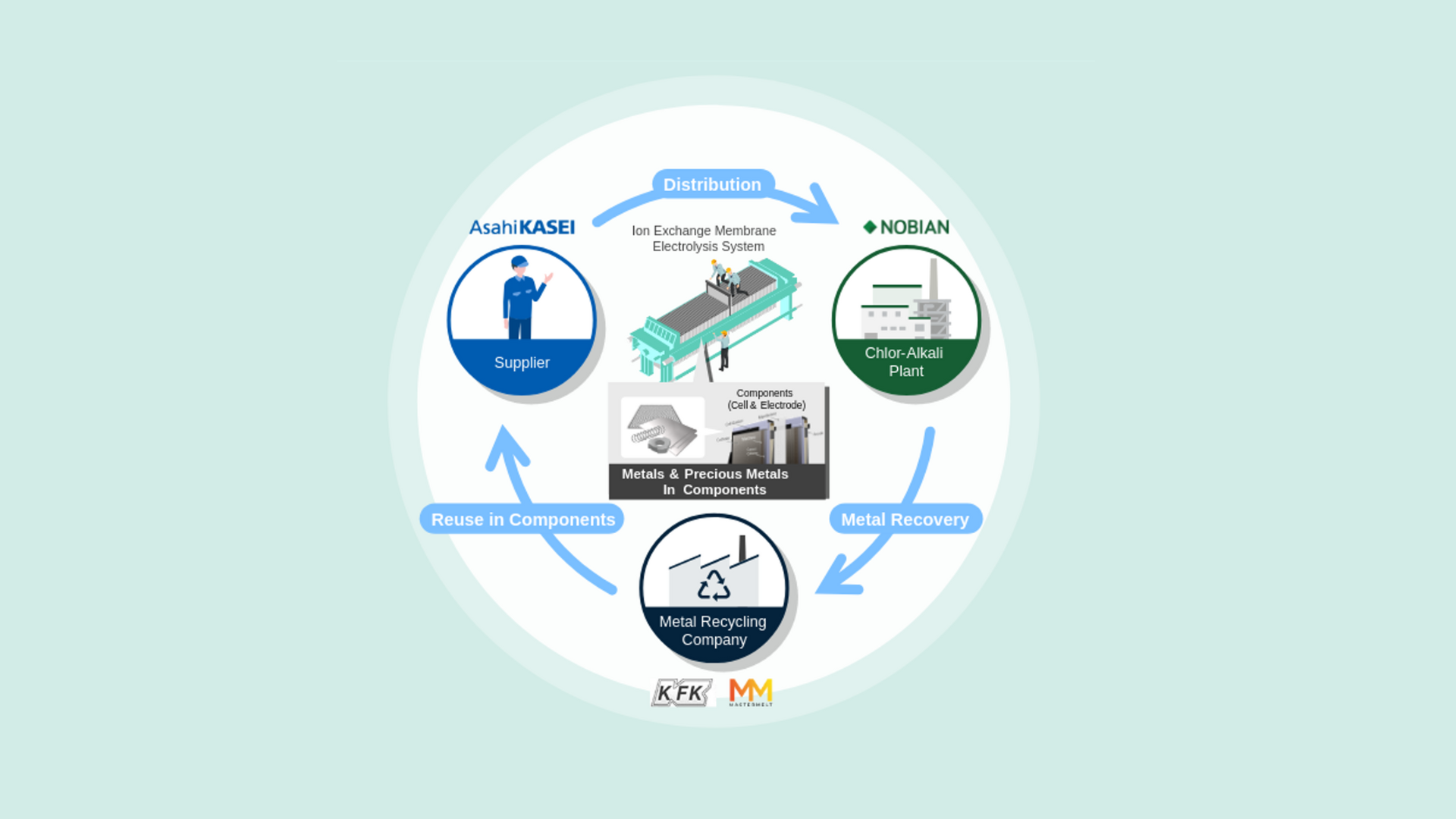

Nobian has over a century of experience in salt production, inorganic chemistry and electrolysis, all key competencies for the development of battery chemicals. Nobian currently produces a range of battery raw materials, such as salt, caustic soda, and chlorine. Building on over 100 years of experience and its existing infrastructure in Europe, Nobian has developed a new lithium chloride conversion process specifically for lithium-based batteries. The new process uses existing industry standard chlor-alkali electrolyzers, making production more cost effective and more sustainable.

Coert van Lare, Director Innovation Program Renewable and Circular at Nobian: 'With our new patent application for the production of lithium hydroxide monohydrate (LHM), we aim to support the sustainable and efficient manufacture of this important battery component. Nobian already plays an important role in the battery value chain by supplying essential chemicals. The new process complements and builds on our capabilities and expertise. By leveraging our energy-efficient, and circular process, we can significantly reduce the costs and CO₂ footprint, and decrease dependence on foreign raw materials.’

Marco Waas, Chief Technology and Sustainability Officer at Nobian: ‘Nobian is committed to being a key player in the production of battery chemicals. Our certified green products guarantee high-quality battery chemicals while minimizing environmental impact. We support sustainable battery technologies by providing a reliable and significantly cost-effective method for the production of battery raw materials. Our new lithium chloride conversion process strengthens the European lithium battery value chain and anticipates the growing demand for lithium hydroxide in Europe. This development fully aligns with our Grow Greener Together sustainability strategy.’

Development and scaling of the technology

Nobian's new lithium chloride conversion process has been successfully tested at pilot scale, at a global, well-respected engineering company active in the construction of lithium production plants, demonstrating its potential. The next step is to scale the process to commercial production. Nobian is in discussions with European and global suppliers to secure lithium chloride, with several parties in the lithium value chain showing interest. Nobian is also seeking investors to scale-up production capacity to meet the growing demand for LHM. While focused on Europe, Nobian is open to licensing its technology, and collaborating, globally.